NOW OFFERING - Air Leak detection with expense reports!!!! Call now to set up appointment.

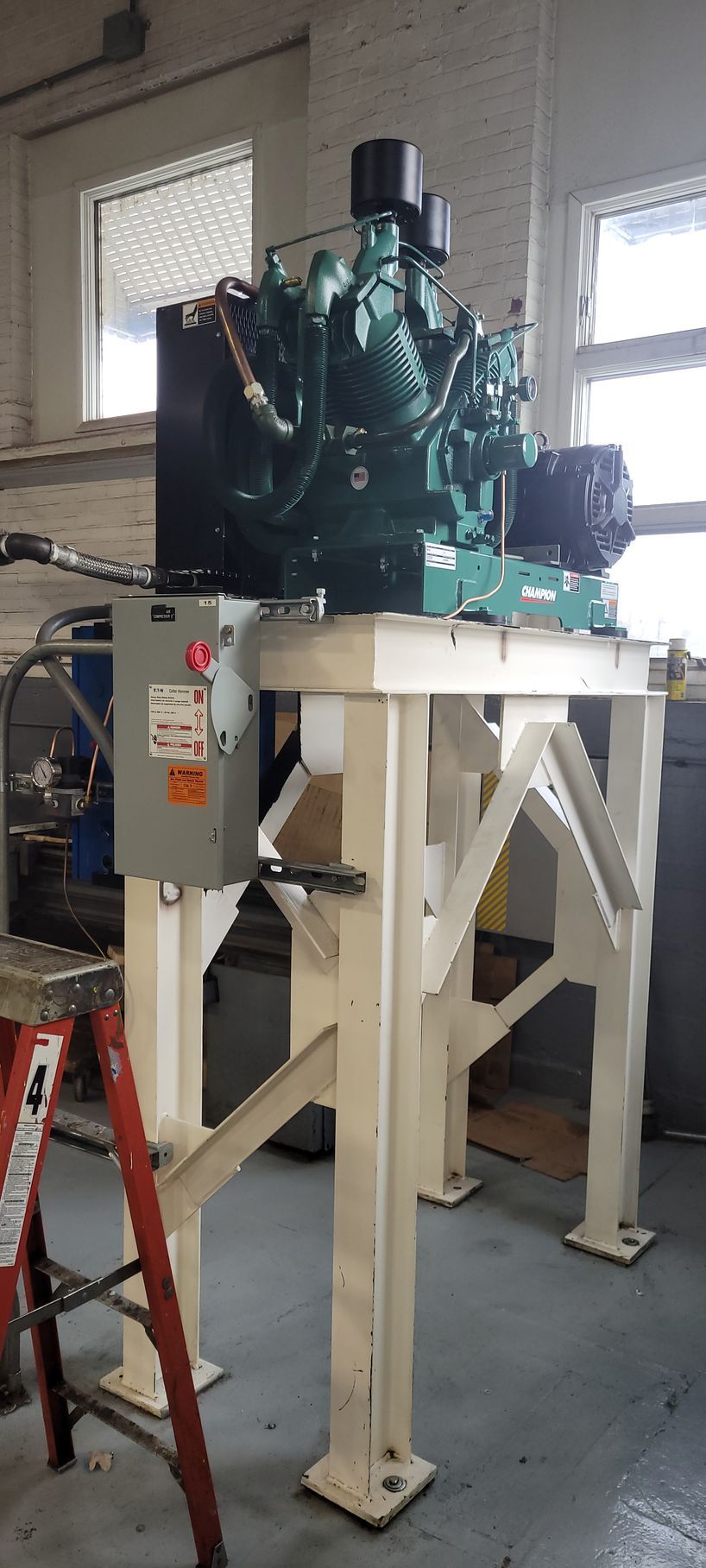

Dependable Compressors You Can Trust

Serving all of Iowa and Southern Minnesota

Leading Company in Air Compressors for Iowa and Southern Minnesota

Compressed Air & Equipment Co. provides air compressors for garage units, commercial and industrial air compressors and rotary screw compressors for those who demand constant air supply. With over 40 years in business, our trained professionals have the knowledge, experience and tools needed to provide you with the best product for your application. We carry a large inventory of parts, lubricants and hoses for most makes and models of compressed air equipment. We are your source for all types of air compressors as well as parts for most brands of compressors on the market today.

About Us

Since 1979, Compressed Air & Equipment Co. has been providing the leading air compression services to Iowa and Southern Minnesota. Our company started out as a one-man business, founded by Rick Foss, and has grown steadily over the years. We are an authorized distributor of numerous major brands of air compressors, air dryers, air treatment, filtration systems, and air accessory products. Our success can be attributed to our commitment to providing the best service technicians in the area.

Frequently Asked Questions

-

Q: Which is best for me, a rotary screw or a reciprocating compressor?

A rotary screw compressor is designed to best operate at 100 % load, 100% of the time. For example, if you are a small mechanic shop with 4 technicians, there will not be a constant air demand and a rotary screw compressor will be loading and unloading frequently, causing increased oil carryover and premature maintenance and repair needs. If you have a continuous air usage a rotary screw compressor would be well suited when sized properly.

-

Q: What makes a cycling dryer better than a non-cycling dryer?

A cycling dryer works similarly to a refrigerator. It cools a thermal mass down to a set temperature and then the compressor shuts off until the thermal mass temperature comes up enough to turn the compressor back on.

A non-cycling dryer compressor runs all of the time and there is a hot-gas by-pass valve that may need to be adjusted as ambient conditions change to maintain a specific dew point range. This makes the cycling dryer more energy efficient and less likely to freeze-up.

-

Q: What is the life expectancy of the oil?

This varies depending on the type of oil. If you are using petroleum oil in a rotary screw compressor, you will need to change the lubricant every 500 to 1000 hours. If you are using a synthetic or partial synthetic, you will have a range between 4,000 hours all the way up to 12,000 hours. Make sure you know what oil you are using, as many lubricants are not compatible with each other.

-

Q: Do I have to use original manufacturer's filters and lubricant?

Most all manufacturers require you to use their filter and lubricant during warranty periods; this ensures that they are protected with products they designed with the specifications they feel are necessary to properly maintain their equipment.

Contact us today at (319) 342-2440 in La Porte City, Iowa, to learn more about our sales, repairs, and rental service of air compressors.

BROWSE OUR WEBSITE

CONTACT INFORMATION

Phone: 319-342-2440 | 800-727-7908

Fax: 319-342-3648

Email: info@compress-air.com

Address: 707 Highway 218 North

La Porte City, IA 50651

PAYMENT OPTIONS

BUSINESS HOURS

- Mon - Fri

- -

- Sat - Sun

- Closed

Emergency services are available!

OUR LOCATION